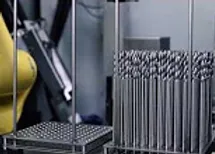

VIKING CNC designed and built a 5-Station, 39-Axis, Modular Transfer Grinder; the VTG-5, to produce surgical bone drills in batches of 120 tools per cassette, with a cycle time of 30-40 seconds including edge preparation, grinding of the end coupling, and size-control check measurement; processes which are almost impossible to incorporate into a conventional machine.The concept of the transfer grinder is to split the grinding process for a particular tool or precision part – split it up into a number of individual, simple, grinding modules which are inter-connected by a conveyor, moving the workpiece between different machining stations, each with their own process and achieving 2µ repeatability.